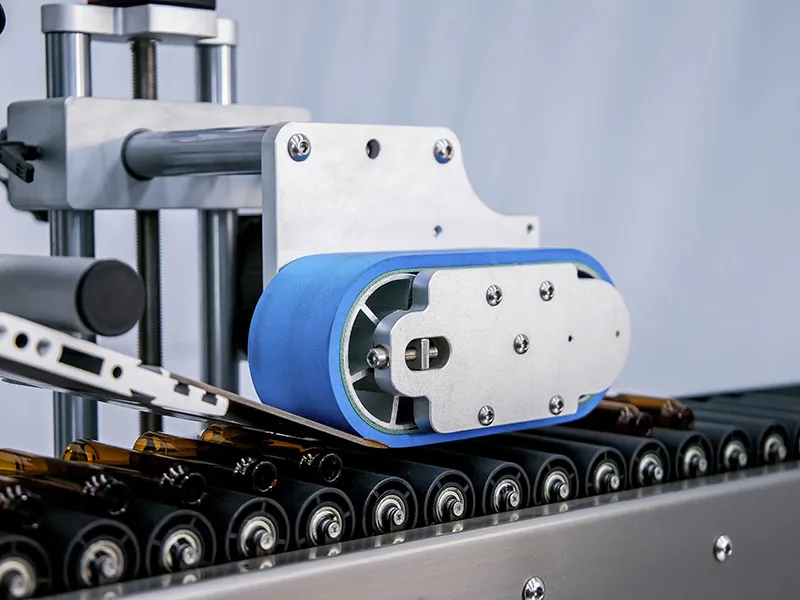

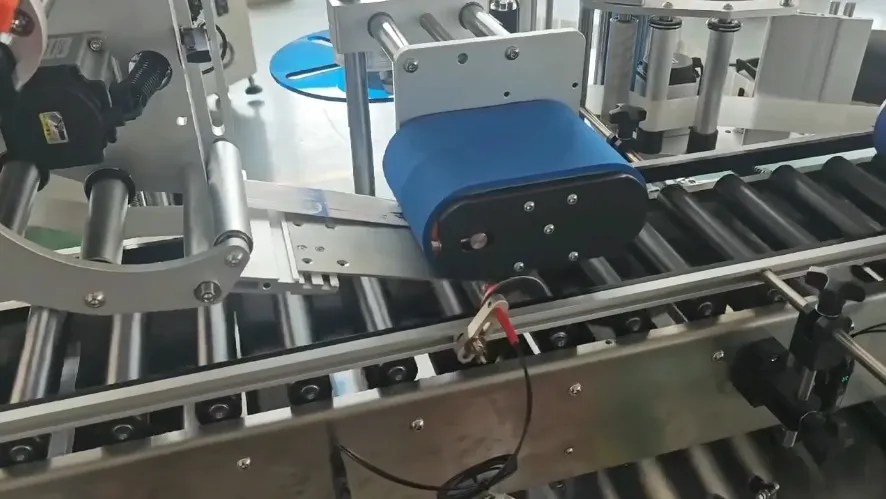

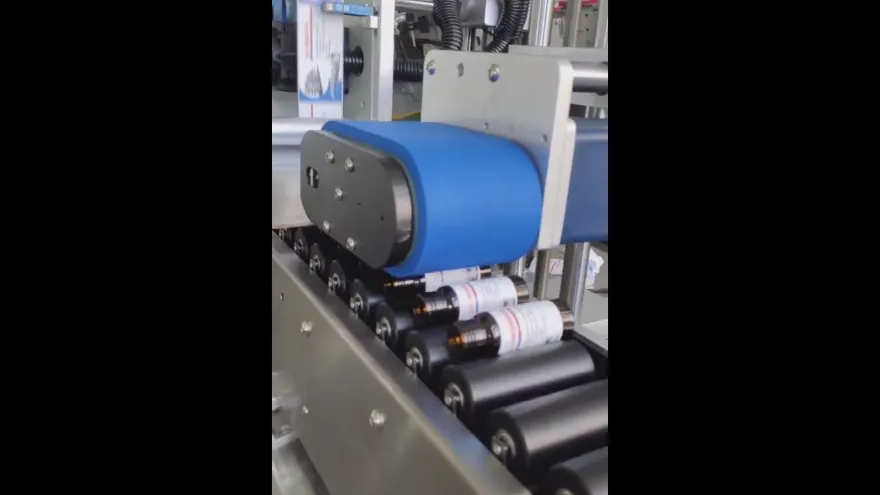

If you’re looking for a solution to label objects that can’t stand upright, this horizontal labeling machine is just what you need! Using a horizontal rolling method, it’s designed to handle your most challenging labeling tasks with ease. It can label up to 200 pieces per minute, making your production fast and efficient. With support for labels up to 60*80mm and precision within ±1mm, you can trust it to deliver accurate results every time. Feel free to contact us to discuss how this machine can enhance your production line and simplify your labeling process!

20 to 200 Products Per Minute

1900×700×1600mm

The fully automatic horizontal rolling adhesive labeling machine is ideal for labeling needs across various industries, including:

Fill in the required fields and let us know your specific needs—we'll respond as soon as possible.