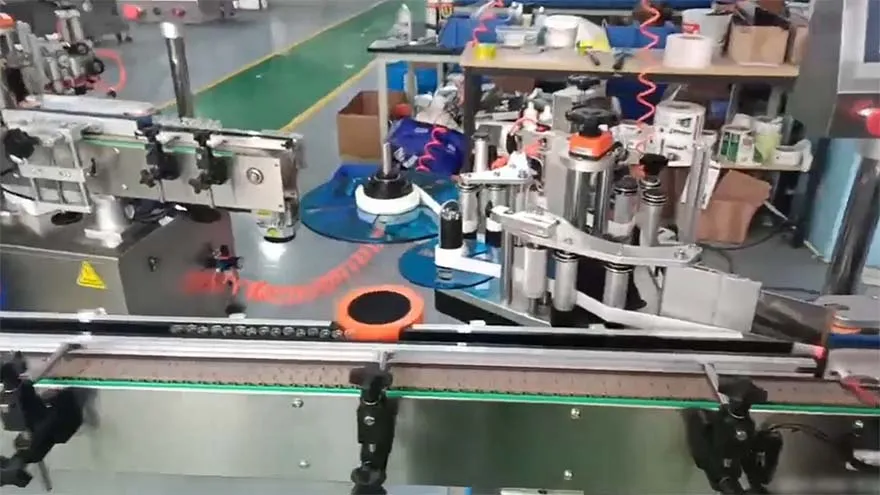

The wrap around labeling machine with wrap belt is perfect for your upright bottle labeling needs! Whether you need it as a standalone unit or part of a production line, it’s built to adapt. With its automatic bottle separation function and 24/7 operation capability, you’ll enjoy uninterrupted performance. The labeling, conveyor, and bottle separation speeds are fully adjustable, giving you complete control to match your production requirements. Plus, it’s built to last with stainless steel and high-grade aluminum alloy, all while meeting GMP standards. Ready to take your production to the next level? Let’s talk about how this machine can help!

20 to 200 Products Per Minute

2000×1200×1300mm

Versatile and efficient, our wrap around labeling machine with wrap belt combines two-side labeling and wrap-around labeling capabilities, making it perfect for single or double-sided labeling of flat, square, and irregularly shaped bottles, as well as full or partial wrap-around labeling of cylindrical objects. It’s widely used across industries like cosmetics, pharmaceuticals, hardware, and plastics.

For example:

Fill in the required fields and let us know your specific needs—we'll respond as soon as possible.